High Performance Conveyor System Parts - Lamella Chain Parts, Lamella Chain For Paper Roller Paper Industrial – Tongbao

High Performance Conveyor System Parts - Lamella Chain Parts, Lamella Chain For Paper Roller Paper Industrial – Tongbao Detail:

| Item Name | Lamella Chain Parts for Paper Mill Chain | Model | Standard |

| Row | Simplex | Application | Machinery Parts |

| Surface Treatment | Self-color/sand-blasted/shot-peening | Certification | ISO, ANSI, DIN, BS |

| Packing | Packaged in boxes and wooden cases | Port | Shanghai or Ningbo |

|

Problem |

Potential Cause |

Solution |

| Chain rises off sprocket | Excess chain slack.

Excess wear at sprocket teeth. Excess chain extension. Foreign material stuck to sprocket teeth. |

Adjust the amount of slack.

Replace the sprocket. Replace the chain. Remove the foreign material from the bases of the teeth. |

| Chain separetes poorly from the sprocket | ·Sprocket misalignment.

·Excess chain slack. ·Excess wear at sprocket teeth. |

·Adjust alignment.

·Adjust the amount of slack. ·Replace the sprocket. |

| Wear to sides of link plates and sprockets | ·Sprocket misalignment. | ·Adjust alignment. |

| Poor chain flexure | ·Inadequate oiling.

·Foreign materials between pins and bushes. ·Corrosion between pins and bushes. ·Sprocket misalignment. |

·Lubricate properly.

·Wash the chain to remove foreign materials,then oil it. ·Replace with an environment resistant chain series. ·Adjust alignment. |

| Abnormal noise | ·Chain is too taut or too loose.

·Inadequate oiling. ·Excess wear of sprockets and chain. ·Contact with the chain case. ·Damaged bearings. ·Sprocket misalignment. |

·Adjust slack.

·Lubricate properly. ·Replace chain and sprockets. ·Eliminate contact with the case. ·Replace the bearings. ·Adjust alignment.

|

| Chain vibration | ·Excess chain slack.

·Excess load variation. ·Excess chain speed leading to pulsation. ·Sprocket wear. |

·Adjust slack.

·Reduce load variation or replace chain. ·Use guide stoppers to stop chain swaying. ·Remove the affected points. ·Replace the sprockets. |

| Damage to pins,bushes,rollers

Deformation of link plate holes |

·Inadequate oiling.

·Jammed foreign bodies. Corroded components.

·Use with greater than allowed load. ·Abnormal load action. |

·Lubricate properly.

·Remove foreign bodies. ·Replace with an environment resistant chain series. ·Review chain and sprocket selections. ·Eliminate the abnormal load,and review chain and sprocket selections. |

| Overall corrosion

Corrosive wear |

·Corrosion due to moisture,acid or alkali. | ·Replace with an environment resistant chain series. |

Applications

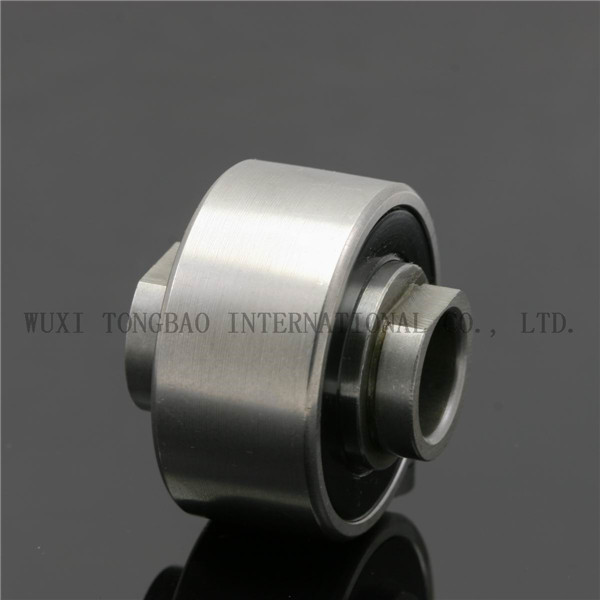

LAMELLA CHAIN PARTS for Paper Mill is special designed to conveyor big paper roll. With pitch 63mm, heavy duty designed, smoothly running by high quality bearing to reduced rolling friction. The V type attachment can be designed according to application. Double chain with attachment also available.

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for High Performance Conveyor System Parts - Lamella Chain Parts, Lamella Chain For Paper Roller Paper Industrial – Tongbao , The product will supply to all over the world, such as: Poland, Macedonia, Karachi, You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly